To maximise the range of vehicles it is necessary to concentrate the gas energy by compression in pressure vessels. This is done by the compressors in the refueling appliances.

In terms of technology, there are two types of refueling appliances with different filling technology:

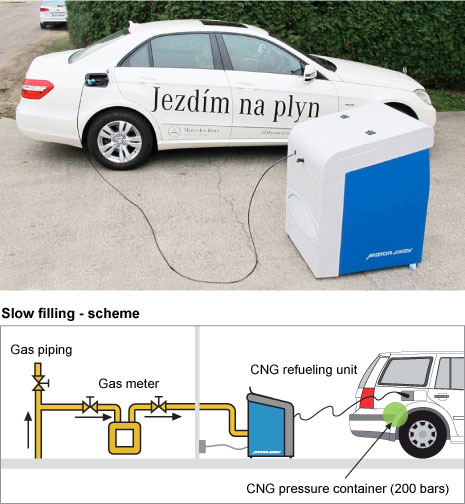

Slow filling – CNG vehicle refuelling appliance

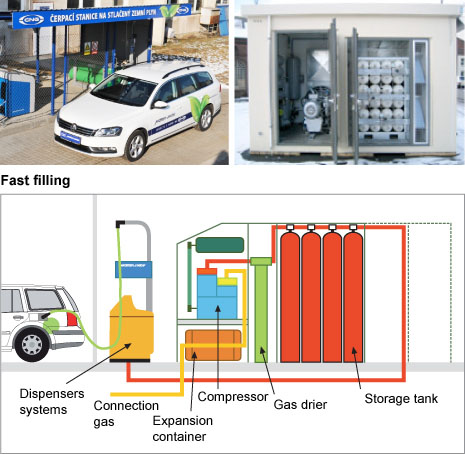

Fast filling – CNG filling station

Slow filling

The compressor compresses the natural gas in real time directly into the car tank (CNG pressure vessel). Filling time depends on compressor power and volume of pressure vessels. This system is the least demanding considering investments and technology, but the disadvantage is longer filling time. Slow filling is typically used in domestic or internal company CNG vehicle refuelling appliances, which usually have an input gas pressure of 0.01 – 0.2 bars from domestic gas supply systems, allowing the user to fill the vehicle when not running, over night or day. They can be used for passenger and commercial vehicles that are not used continuously. Technical and legislative conditions for installation of these units are minimal and on certain conditions they can be situated inside buildings, e.g. in a garage. The standard output of these refueling appliances is up to 20 m3/hour.

Example of filling speed

Volkswagen Passat Variant 1.4 TSI EcoFuel, CNG tank of 21 kg, MJ Compact 05 vehicle refuelling appliance with 5 m3/hour output = 3.6 kg/hour. Filling time of empty tank is 5.8 hours.

Fast filling

The compressor compresses the natural gas into interconnected pressure storage tanks. The actual filling of the vehicle is done using a dispenser or a device that fills the compressed gas from the gas storage tank to pressure vessels in the vehicle. Filling takes between 2 and 5 minutes and it is fully comparable to filling standard fuels at a petrol station (petrol or diesel). Compressors compress gas to pressure storage tanks before filling so that the tanks are continuously full and available for filling. This solution is used at public CNG filling stations, their disadvantage is a higher initial investment. The output of these stations is usually over 20 m³/hour.

The most important manufacturer of filling technologies is MOTOR JIKOV Strojírenská.

Filling stations

Approximately 50 filling stations are currently available to Czech motorists and their number is growing. Of this amount, about forty are public. Over one hundred domestic units are also in operation. The demanding storage of CNG and higher investment costs for building filling stations are the reason why CNG vehicles are used mainly by local operation fleets, e.g. local public transport operators. Česká pošta (Czech Post) is planning to invest heavily in CNG vehicles. The company has already purchased 412 CNG-powered passenger and commercial vehicles. Its target is a fleet of 2,900 CNG vehicles. The State Labour Inspection Office is preparing to rent 180 vehicles and 46 small vehicle refuelling appliances.

Small vehicle refuelling appliances are an optimal solution for extending the existing network of filling stations. MOTOR JIKOV Strojírenská plans the production of several hundred vehicle refuelling appliances this year. The vehicle refuelling appliance is represents state-of-the-art technology for slow filling. For fast filling, the MJ Variant filling station is more optimal in terms of technology. The MJ Compact 05 CNG vehicle refuelling appliance won the prestigious E.ON Energy Globe Award Czech Republic 2011 in the Air category.